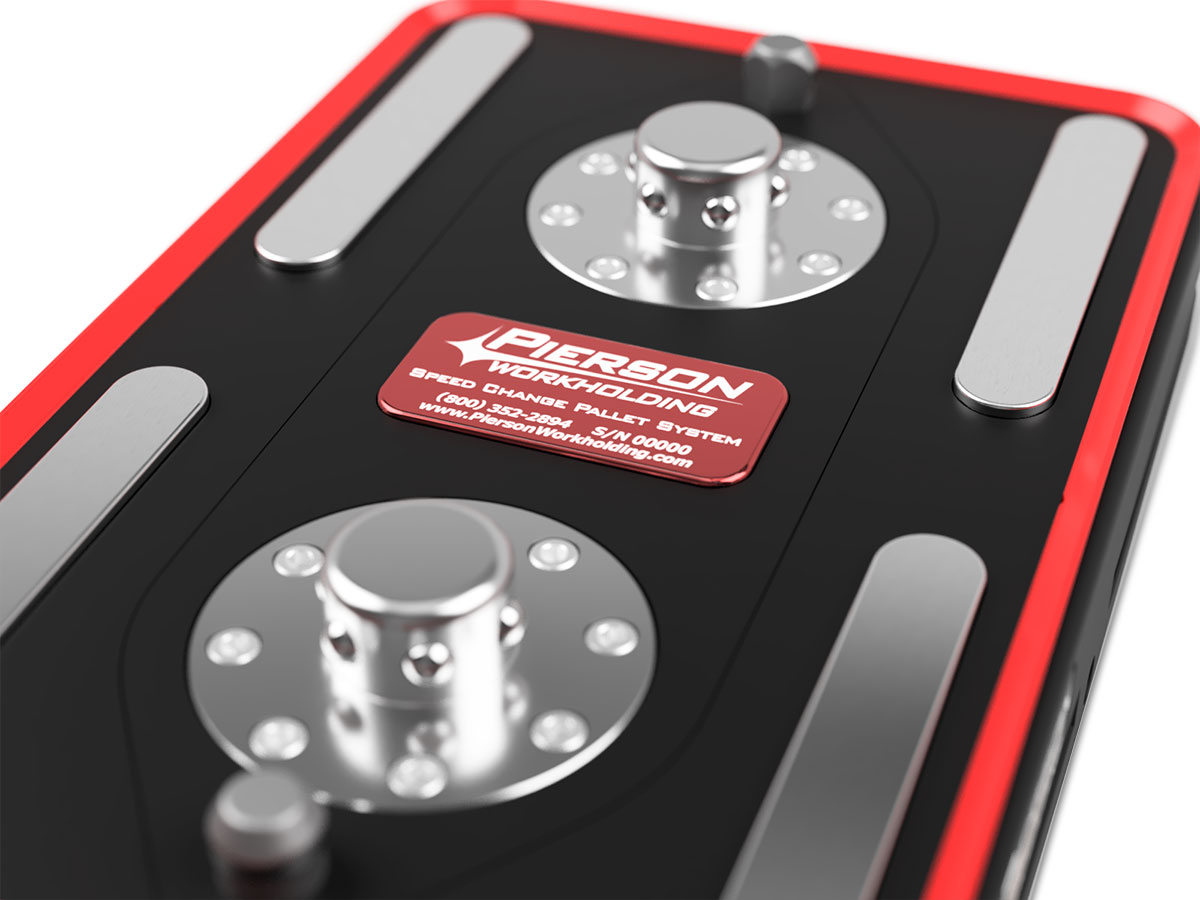

The Pro Pallet System

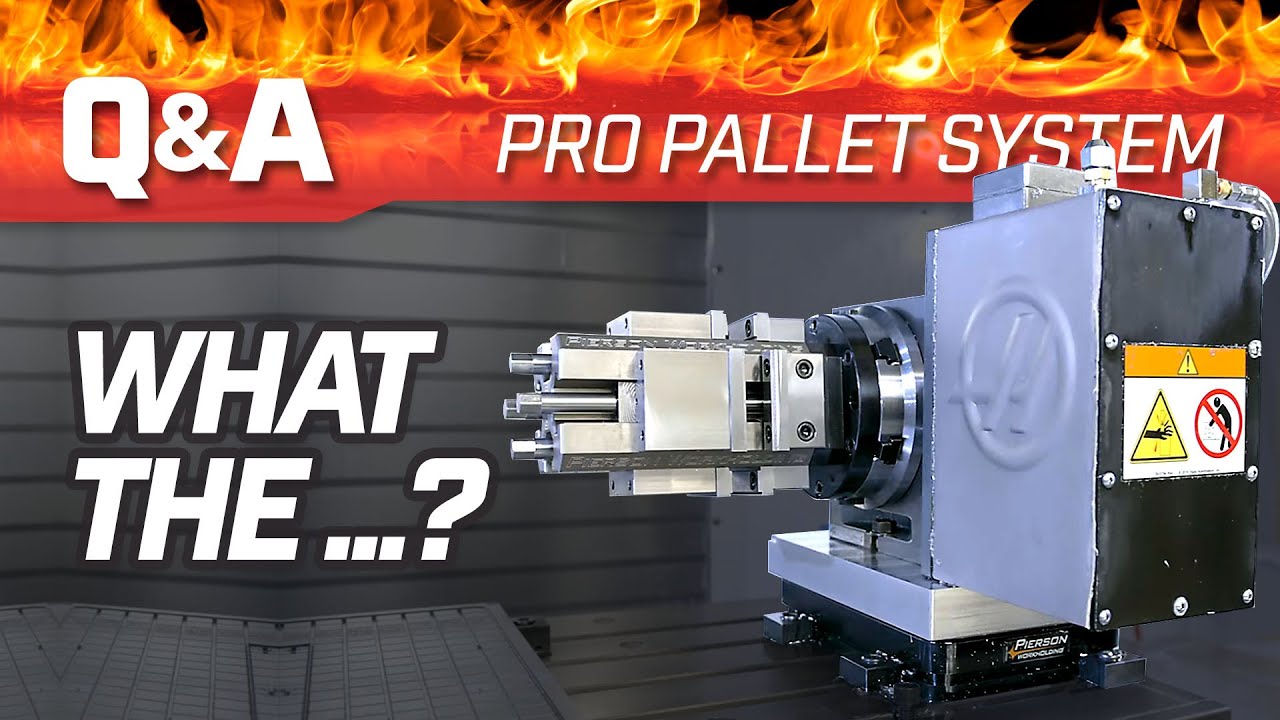

Our 4th generation Pro Pallet System (PPS) builds on over a decade of refinements. The PPS is a high-density workholding solution designed to eliminate bottlenecks by allowing more parts to be held AND moved in and out of the machine faster than any other workholding method. The universal Base accepts four standard sizes of pallets. This manual pallet changer simultaneously improves productivity by reducing labor and idle spindle time.

Pro Pallet System

Starter Package

The Pro Pallet System (PPS) Starter Package streamlines purchasing. Click below and select the size of pallets you want with the package.

$2,910.00