Pro Pallet System

DOWNLOADS

Printables: PPS Flyer (PDF) |

PPS Manual (PDF) |

PPS Base Dimensions (PDF) |

PPS Pallet Drawing for Hardware Kit (PDF)

Models: PPS model for Fusion 360 |

PPS Base model in STEP format |

PPS Pallet model in STEP format

FAQs

Look at any high production machine out there and you'll see pallet changers, tombstones, and high density workholding fixtures. The industry has figured out that to maximize profits you have to maximize spindle time.

The more parts you can get in a machine per cycle and the faster you can get them in and out translates into bigger profits. The problem is that these "efficiencies" have such a high initial cost that you might not see any return on investment until several years down the road.

The Pierson PPS provides all the efficiencies of high density workholding and fast part change-outs without the astronomical price tag.

Yes! Three options are available. First, we can make custom oversized pallets. Give us a call or email for exact sizing and pricing. Second, YOU can make an oversized pallet using our PPS Hardware kit. Make sure to watch this video to program your part for best success. Finally, a custom double receiver pallet is an option for holding one large pallet using two bases. Contact us for details.

A PPS will work with any vertical machining center or knee mill. The Connection Kit contains all the components needed (air fittings, air lines, hand valve, grommets, instructions) to begin using the PPS in your machine. The only other thing you'll need to provide is an air source with a minimum of 100psi for operation.

Mounting the PPS Base is easy. The PPS Base mounts to your table with the same T-slot nuts that a standard vise uses. We even include the toe clamps and bolts.

Vises have been around for a long time and have their right place in manufacturing. High density workholding systems don't have much benefit on prototype and short run jobs, but they are not always for holding parts! Check out this video to see how customers standardize vises, indexers and clamping fixtures for single minute setups. Imagine bolting your current vises and rotary indexers to pallets and simply dropping them onto your table with no need to indicate them ever again! For more ideas on what people are mounting to their pallets, check out our Instagram feed.

Not at all. The PPS still maintains a tremendously high locking force of over 3000 lbs due to its powerful springs. This is more than enough to maintain a secure hold. Plus, other systems use hydraulics which can be a great liability of losing holding power should the hydraulic pump fail. The PPS is designed to be failsafe. The air lines can be completely removed and the system will continue to stay locked.

Spreading a light coating of grease on the alignment pins and locking bearings is all you'll need to do to ensure consistent holding force. This should be done on a regular maintenance schedule as outlined in the PPS Manual. Because all critical components are hardened, the system has shown very little wear after 100,000 test cycles. We've found that the best preventive maintenance is to keep everything clean, covered and dry when not in use.

Yes, substituting a different size pallet for the 8 x 12 that comes with the Starter Package is not a problem. Our workholding store will automatically quote the price for different pallets.

All of our products can be purchased directly through us. This allows us to establish a close relationship with our customers and provide the best applicaton advice possible. Click here to order online or give us a call to place an order at (800) 352-2894. We accept all major credit cards and company checks.

Mini Pallet System

DOWNLOADS

Printables: MPS Manual (PDF)

Models: MPS Model for Fusion 360 |

MPS Model in STEP format

NYC CNC: Making the MPS part 1 Full Length

Pallet System Q&A | Purchase a PPS here

FAQs

The Mini Pallet System is built with the same basic components of the Pro Pallet System, but with the roughly half the components and cost. The MPS is best suited for lighter machining applications (spindles under 7 horsepower). The base lacks a perimeter seal so air/mist coolant is preferred over flood coolant but still functions perfectly in any cutting conditions.

The repeatability of the MPS is .0003" - the same as the PPS. However, the MPS lacks a cast iron core which makes it more sensitive to large temperature fluctuations that could change accuracy up to .001".

In short, very rigid. Bolting the base down with 2 included toe clamps is sufficient, but the question arises about the overhang of the pallets. For this reason, we've limited the maximum pallet size to 8" x 14". 2000 lbs of force at the corner of the larger pallet can flex it up to .004" in Z, but stable in X and Y. However, in reality no drill or endmill exerts this much force without breaking.

The MPS uses tight tolerance components that depend on equally tight tolerance machining of the aluminum pallet. For this reason, we prefer to manufacture all pallets in-house so that performance will not be affected. One workaround is to use our pallets as a master in which the user can bolt on other fixture plates.

All of our products can be purchased directly through us. This allows us to establish a close relationship with our customers and provide the best applicaton advice possible. Click here to order online or give us a call to place an order at (800) 352-2894. We accept all major credit cards and company checks.

SmartVac Vacuum System

DOWNLOADS

Printables: SmartVac Flyer | SmartVac Manual

Models: Models available after purchase. Please email us and mention your order number (W-xxxx) at questions@piersonworkholding.com.

FAQs

The US short answer - Multiply a part's surface area (exposed to the vacuum) in square inches by 14 to find the downward holding force in pounds.

The Metric short answer - Multiply a part's surface area (exposed to the vacuum) in square mm by .0098 to find the downward holding force in kg.

The long answer - The holding power of any vacuum chuck system is measured by the amount of air it can remove from under a part. You'll see vacuum ratings measured as "Inches of Mercury" or "Hg. A perfect vacuum, like outer space, would equal 29.9" Hg. It takes a lot of energy to create a perfect vacuum on Earth however the SmartVac vacuum chuck draws a 94% or 28" Hg vacuum using only 0.8 cfm or compressed air! This is equal to 14 psi of downward holding force. This means a 6" x 6" part will be held with a force of 504 pounds (36sq.in. x 14psi = 504lbs) or a 150mm x 150mm part will be held with a force of 221 kg (22500sq.mm x .0098 = 220.5 kg).

The perfect part has a large surface area and with a small thickness cross section. Materials can range from plastics to metals. Harder materials can increase side loads during cutting which can slide a part off the chuck so lighter feedrates and depths of cut should be observed. One tip to overcome part movement is to sandwich a piece of 400 grit sandpaper between the chuck and the part to increase friction. Watch this video that explains this concept in further depth:

The heart of the system is our Vacuum Power Unit (VPU). The VPU draws a vacuum equal to or greater than conventional vacuum pumps. Plus, the system is low maintenance since it does NOT require particle filters or coolant traps. Other systems require an electrically powered pump where the SmartVac 3 runs off a small amount of compressed air - only 0.8 CFM! The chuck portion of the system has nine vacuum inlets allowing up to nine individual parts to be held simultaneously where other systems only hold one part at a time. Pricewise, the system is less expensive to purchase AND maintain than comparable, traditional systems.

This is easily done by attaching a Top Plate to the vacuum chuck surface and milling a gasket groove just inside the part's perimeter. Any through holes in the part need to have gaskets around them so the vacuum isn't lost when a cutter breaks through the bottom surface of the part. If the finished part has very thin features (imagine cutting out the letter O), consider leaving .005" to .010" of material at the bottom (the inside of the O) to maintain a larger vacuum area. Depending on the material, you should be able to easily peel out the center section by hand.

For all sizes of gasket, the groove width should be 95% of the nominal gasket diameter. The groove depth should be 80% of the nominal gasket diameter. This means our 1/8" gasket should have a width of .118" and a depth of .100". The same formula for a 1/4" gasket comes out to .238" wide and .200" deep. For best results, add at least a .015" chamfer to the top of the groove. Our Gasket Slotting Endmill makes perfect grooves. The material has a foam core and should compress into the groove and never get pinched between the bottom of the part and top of the chuck.

Yes! The SmartVac is perfectly suited to handle large parts. Multiple bases can be setup adjacent to each other using a Twin Base Kit. This kit contains everything needed to chain multiple bases together and operated by one VPU.

We also make custom oversized top plates if you don't mind a little overhang. Check out our library of sizes of Custom Top Plates.

Yes, however keep in mind that a part(s) across multiple chucks must seal on them simultaneously for the vacuum to draw. One VPU is required for roughly 160 linear inches of vacuum gasket length. The recommended number of chucks that one VPU can reliably power is as follows:

- Three 9.5" x 14" Chucks

- Three 13.5" x 13.5" Chucks

- Two 13.5" x 20" Chucks

- One 13.5" x 30" Chucks

- One 18" x 24" Chucks

As you may find, the maximum gasket length of 160 inches means that the surface area (which translates into holding force) can vary widely. For example, these shapes all have the same 160" gasket length but different holding forces: (Holding force = area x 14)

- 50.93" dia circle = 28,518 lbs of holding force

- 40" x 40" square = 22,400 lbs of holding force

- 75" x 5" rectangle = 5,250 lbs of holding force

All of our products are sold direct. This allows us to keep prices low and to establish a close relationship with our customers to provide the best applicaton advice possible. Click here to order online or give us a call to place an order at (800) 352-2894. We accept all major credit cards and company checks.

Vacuum Workholding Tips

- Vacuum Power has an Upper Limit – The absolute maximum vacuum power any vacuum pump can achieve on Earth is 14.9 pounds per square inch at sea level. This is because the weight of air around us is what actually pushes the part down onto the chuck.

- Vacuum Workholding is Often a Secondary Choice – Yes, vises and clamps are the preferred method of holding a workpiece due to theoretically unlimited clamping force, however thin parts aren't easily held with a vise. A vacuum chuck may be your only choice, but don’t expect to be able to machine a part as aggressively as when using a vise. For example, a 3" square workpiece will only be held with 126 lbs of downward force and a 10" square workpiece is held with 1,400 lbs.

- Use Common Sense – Holding a part that is 1 inch square and 4 inches tall is not going to hold up against cutting forces. Short and wide parts that absolutely cannot be held with a vise are the best candidates for vacuum workholding.

- Use Workstops Whenever Possible – Side loads are the enemy of vacuum applications! Though vertical holding force may be high, cutting forces can shift a part sideways, especially when machining plastics with a low friction coefficients (nylon, teflon, delrin). Adding pins, side rails or following the best practice of cutting a shallow pocket in one of our customizable Top Plates for the part to sit in will maximize sideways rigidity.

- Use Small Cutters when Possible (if you’re not following tip #4) – Small cutters exert less torque, reducing side forces thereby reducing the chance of sliding a part off the chuck. Instead of taking a 1/2″ wide cut around a part, use an 1/8″ cut with four passes.

- Use Sharp Cutters – Sharp tooling naturally exerts lower side loads which reduces the chances of a part sliding on a chuck.

- Use 45 Degree Helix Endmills – Low helix cutters won't lift a part, but they exert higher side loads. 45 deg cutters split the difference between lifting and sliding forces.

- Flexible Workpieces Might be Problematic – Because the rigidity of the workpiece helps maintain a vacuum seal, very thin or very soft materials may be more likely to flex at the edges and peel off the vacuum chuck. Use reverse helix cutters that have a downward cutting action and follow the 3 C's:

- The 3 C's of reverse helix cutters – Coolant: Have adequate coolant or air to help with chip evacuation since chips are forced downward. Clearance: Machine a clearance trough in a Top Plate along the edge of the cut so chips have a place to go. Corners: Outside corners have minimal support so slow down. Inside corners have good part support but more of the tool is engaged in the cut so side loads are higher than normal so slow down here as well.

RotoVise Pro

DOWNLOADS

Printables: RotoVise Flyer (PDF) | RotoVise Quickstart Guide

Models: RotoVise Pro in STEP format

NYC CNC: RotoVise Oversize Aggressive Machining Full Length

FAQs

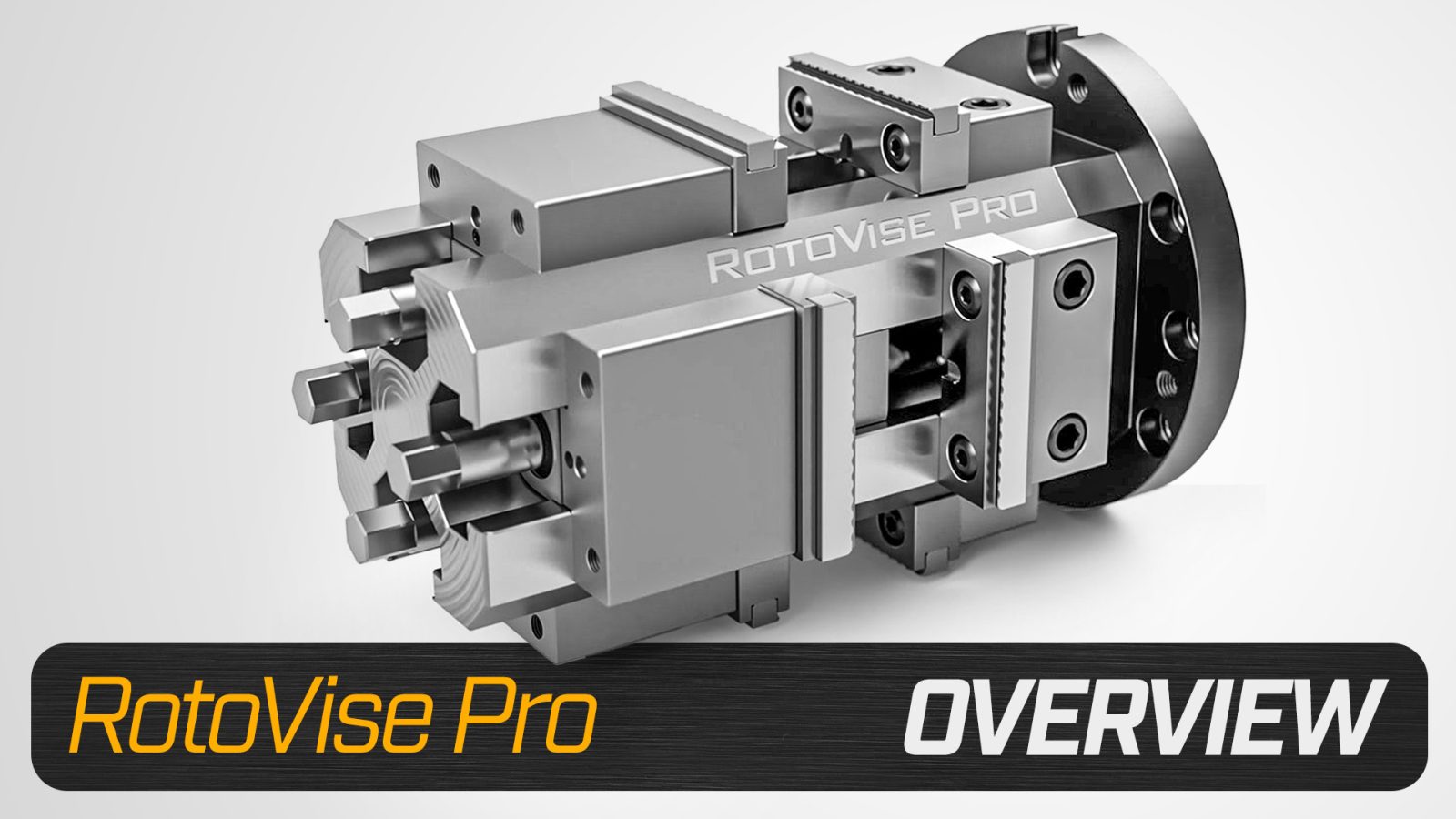

Simply put, a tailstock is NOT needed. Because of the compact length, rigid materials and parts held closely to the rotary table face, tailstocks have no effect on performance. We've rigorously tested the RotoVise for over four years and have cut aluminum, steel, stainless, cast iron and hardened alloys with excellent results and surface finishes at aggressive feed rates (250-600 ipm depending on material) without the need for a tailstock.

As previously mentioned, we've machined aluminum, steel, stainless, cast iron and hardened steels during the two year development of the RotoVise. In fact, most components of the RotoVise are made on the RotoVise! For comparison, we machine the ductile cast iron sliding jaw carriers at 300 ipm, .750" doc and .050" woc with a 4 flute 1/2 inch diameter carbide endmill with amazing results.

The RotoVise is designed to bolt to all brands of rotary tables that use 4 or 6 t-slots platters as well as all Haas Automation UMC models. For best results, only use rotary tables that have integrated pneumatic brakes that provide a minimum of 100 ft-lbs (136 Nm) of brake torque. Manual rotary tables also work well as long as they have a manual brake.

Each jaw station grips with up to 5,000 lbs of clamping force. Let's think about this... a good conventional 6 inch vise clamps with about 8,000 lbs. With only 3 inch wide jaws, the RotoVise has an equivalent clamping force of 10,000 lbs on half the width compared to 6 inch vises. Furthermore, the RotoVise uses a fine pitch 16 tpi lead screw to exert more clamping force for the same torque input. We've designed this to minimize torque placed on the rotary unit without compromising clamping force.

45 foot lbs maximum.The RotoVise uses a finer pitch lead screw (16 tpi) than traditional vises (10 tpi). This means the same amount of handle torque applies 60% more clamping force than a standard vise. For this reason, only the 3-arm handle supplied with the RotoVise should be used because the shorter handles limit the amount of torque applied to the brake and gears of the rotary unit.

All of our products can be purchased directly through us. This allows us to establish a close relationship with our customers and provide the best applicaton advice possible. Click here to order online or give us a call to place an order at (800) 352-2894. We accept all major credit cards and company checks.